No, “Listen to the Things” isn’t some sort of zen lesson, although it could be!

It is one of my occasional series of “Essential Truths of the IoT“: fundamental underlying principles that are essential to understanding the true nature of the Internet of Things as a fundamental paradigm shift.

I think particularly of General Electric when I think of this fundamental principle, because GE is turning “listening to things” into major innovations in product design that, in turn, are leading to new ways of marketing their products and new revenue streams.

For example, not only is GE able to optimize production of the advanced cell-phone tower batteries at its state-of-the-art factory in Schenectady, NY because of 10,000 sensors on the assembly line, but also the batteries themselves include built-in sensors that allow GE to monitor their condition.

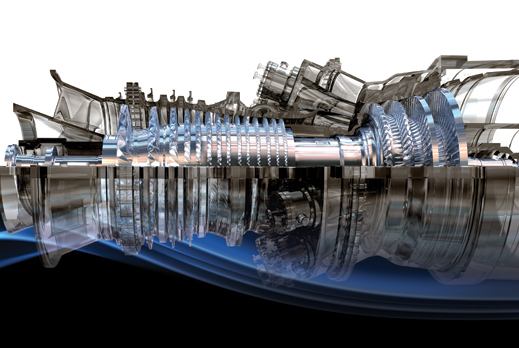

Thinking in terms of “listening to things” has revolutionized the very way GE markets its jet engines. Some of its new engines contain 20 sensors, which can generate up to a were 20 sensors that monitor the engine’s performance, generating up to a terrabyte of information on a cross-country flight. That allows the airline user to do “predictive maintenance,” which uses actual data on the actual engine — not just some recommended service interval for engines in general, to determine when that specific engine needs maintenance for best performance.

It also gives GE the option of leasing the engine instead of selling it, with the actual price of the lease again dependent on the actual usage of that particular engine, rather than some arbitrary average.

The customer also benefits — as does the global environment. GE calculates that if “an average-sized airline used F&CS (Fuel and Carbon Solution to achieve a 2% improvement in fuel consumption, it would be equivalent to removing more than 10,000 cars from our roads.”

Here’s the problem — and the opportunity. We’re used to “dumb things” that were inscrutable — you couldn’t “listen” to how they were actually operating if your life depended on it. As a result, we don’t automatically see the opportunities to redesign products to include sensors that will automatically report real-time data about their operating state and possible problems. To capitalize on this “Essential Truth” of the IoT we will have to start asking a new question:

what things that are part of our intrastructure and/or our products

can be redesigned so we can “listen” to them — and

learn from them?