OK, the Internet of Things is officially a Big Thing: Tom “World is Flat” Friedman wrote about it in the Sunday NY Times.

Friedman, searching for evidence of American “exceptionalism” in a bleak landscape of Capitol Hill paralysis, etc. zeroed in on GE’s “Industrial Internet” initiatives as a ray of hope. As he wrote,

“I wanted to see what new technologies, and therefore business models — and therefore jobs — it might be spawning that public policy, and education policy, might enhance. I have no idea whether or how G.E. will profit from any of these breakthroughs, but I saw the outlines there of three radically new business trends that the United States should want to dominate.”

One of those themes was how 3-D printing could streamline the design and production process.

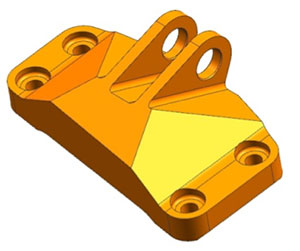

The second, which I wrote about earlier, was the concept of crowdsourcing design, in particular the contest GE held to design a new jet turbine mount (more about that later!!!).

Finally, Friedman zeroed in on the IoT, specifically widespread use of sensors:

“Lastly, we are on the cusp of what G.E. calls ‘the Industrial Internet’ or the ‘Internet of Things’ — meaning that every major part of a G.E. jet engine, locomotive or turbine is now equipped with online sensors that constantly measure and broadcast every aspect of performance. Computers capture all this big data and use it to improve everything from the flight path to energy efficiency.”

He gave several examples, such as wind turbines and hospital beds, where data from sensors can help to optimize efficiency and cut operating costs. He pointed out that the data allows GE to create new services “… that offer not just to manage an airline’s or railroad’s engines, but how fast all its planes or trains go, how flight and train schedules are coordinated and even how its equipment is parked to get optimal performance and energy efficiency (aside to marketing managers: what kinds of services would the IoT allow you to introduce, perhaps replacing actual sales of products with leases based on use? Think about it!).

Friedman concludes, “Watch this space, even if Washington doesn’t: When everything and everyone becomes connected, and complexity is free and innovation is both dirt-cheap and can come from anywhere, the world of work changes.”

Indeed! Nice to have someone with Friedman’s clout recognizing the IoT is a paradigm shift!

MEANWHILE: Make certain to read the comments following the column. They are primarily negative, and zero in on one thing: the IoT’s threat to jobs. In particular, the critics focused on the GE engine mount design contest. One was particularly pointed:

“According to CNNMoney, General Electric CEO Jeffrey Immelt pocketed $25.8 million in total compensation in 2012. That’s about $20,000 every hour and a half. How come 8 geniuses cost only 90 minutes of CEO time?”

You’ve gotta agree, $20,000 ($7,000 to the winner) is a pretty paltry sum considering what GE gets in return, and given readers’ suspicions that companies may let go their salaried designers and instead exploit freelancers (I’ve thought the same about some of the incentives offered by Innocentive member companies for some of the crowdsourcing projects that they’ve offered), you can bet that there will be more criticisms in the future if this becomes a common practice.

The IoT will undoubtably result in loss of some jobs — disruptive technologies do that — although optimists say they will create jobs as well. But if companies don’t want to reap a lot of criticism for their IoT initiatives, they’d better put some thought into the job creation aspect as well!